ABSTRACT

The use of composite materials in construction applications has progressed significantly

over the last few decades. Steel concrete composite systems are becoming very common as

they combine to build structures that are stiffer, lighter, and less costly. This paper explores

the ultimate strength of the composite floor system of structural steel concrete. ABAQUS,

used to research non-linear competencies and ultimate load-carrying capability of such

floor systems, developed the Finite Element Model (FEM) in 3-D. Eighteen numerical

models were developed to simulate the behavior with published literature using Finite

Element model. The concrete damaged plasticity model and elastic-perfectly plastic model

have been used to simulate the concrete and material nonlinearities were included in the FE

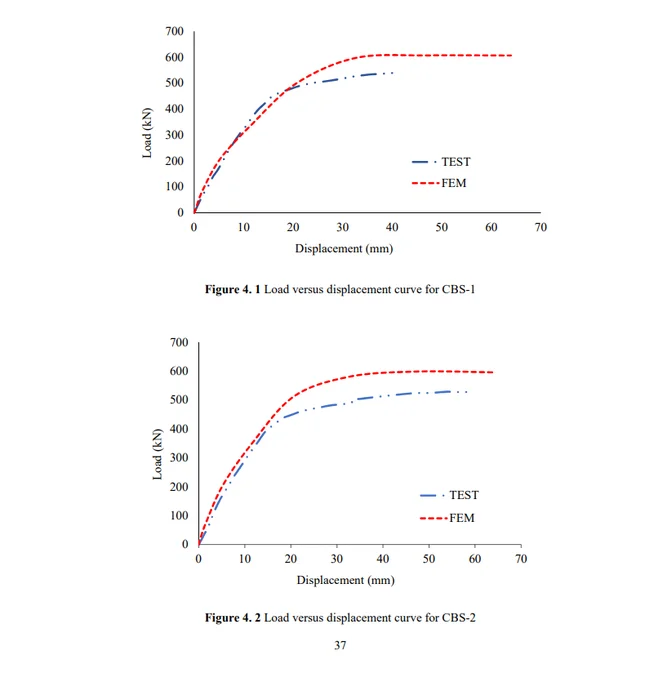

model. A comparison of computed values with experimental results has validated the

proposed finite element model. The measured and experimental findings show a good

match with an average variation of 7.125% for ultimate capacity. The experimental results

can be estimated with a high degree of accuracy using the FE model. An extensive

parametric study has also been carried out. In previous studies the main focus was on the

types and effect of different parameters of shear connector on composite structure but in

this study individual parameter of shear connector has been explored. In this parametric

study effects of different sizes of shear studs have been explored on full size beam

specimen. Results show that an increase in height of the shear stud with the same diameter

increases the ultimate capacity of the floor system. Ultimate capacity of the floor system

increases 2.68 % for 20 mm increase of height on an average for a fixed diameter shear

stud. Ultimate capacity of the floor system increases 1.96 % for 3 mm increase of diameter

on an average for a fixed height of shear stud.